When exactly was the last year of Tenifer for US pistols ? I hear 2008 , 2009 , and so one. Do anyone of you guys/gals have a definite date of when Glock stopped using Tenifer on US guns ? Any help is appreciated .

-

Glocktalk is a forum community dedicated to Glock enthusiasts. Come join the discussion about Glock pistols and rifles, optics, hunting, gunsmithing, styles, reviews, accessories, and more!

Tenifer dates

tercel89

Discussion starter

5,192 posts

·

Joined 2005

- Add to quote Only show this user

When exactly was the last year of Tenifer for US pistols ? I hear 2008 , 2009 , and so one. Do anyone of you guys/gals have a definite date of when Glock stopped using Tenifer on US guns ? Any help is appreciated .

17,610 posts

·

Joined 2009

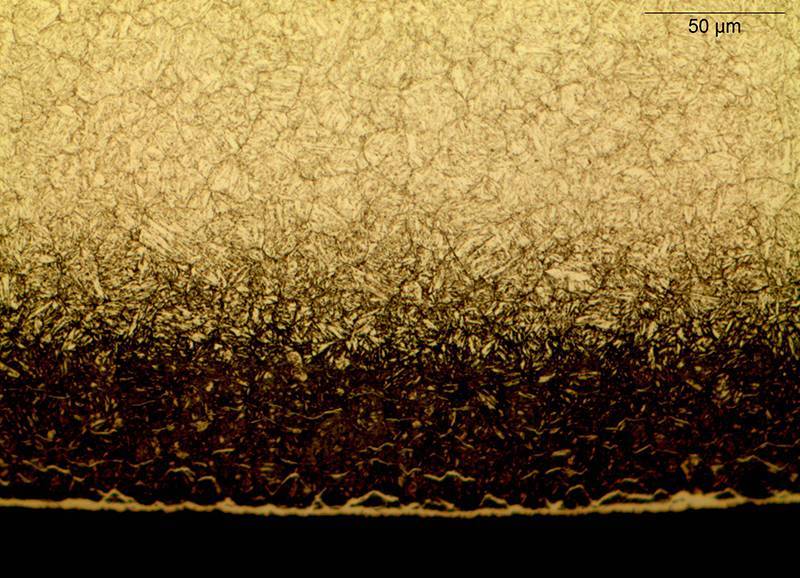

Unless you are a metallurgist, you would be hard pressed (unbiased) to prove a performance difference between Tenifer, and it's replacement process.

Remember that the Tenifer is the treatment of the steel before the visible black finish is applied.

Remember that the Tenifer is the treatment of the steel before the visible black finish is applied.

34,459 posts

·

Joined 2009

This quotes 2010.

Glock Ges.m.b.H., an Austrian firearms manufacturer, utilized the Tenifer process until 2010

Glock Ges.m.b.H., an Austrian firearms manufacturer, utilized the Tenifer process until 2010

50,944 posts

·

Joined 2002

Don't remember. In one of my recert classes the Glock instructor mentioned they had changed their 'nitration' method. Seemed a bit vague, but then most armorers weren't concerned about it. Going from bath nitriding to gas nitriding resulted in less toxic byproducts. The push for 'greener' less toxic methods was a concern even in the EU.

17,610 posts

·

Joined 2009

Any large scale industrial chemical process has the potential for "toxic byproducts"- those companies that do it responsibly aim for a cleaner environmental footprint.

The chemical process itself is a common industrial ( chemical) steel treatment process - done without a brand name attached. This process is NOT "banned because of cyanide".

Contrary to the MYTH : Glock did not stop using Tenifer because of US environmental or EPA concerns. Salt bath nitriding is a common steel treatment and STILL currently done by many companies in the USA -- look it up-- there might be a company in your city doing it.

Tenifer is a European registered brand name - still used by other companies. Melonite is a USA registered name for the same process. That same process can also be generic. Clorox is a brand of bleach, and Morton is a brand of salt -BUT not all bleach is Clorox brand, and not all salt is Morton brand. The chemicals are the same.

You can reach the same terminal endpoint result with various approaches to steel "NITRIDING" (the generic term for what Tenifer does to the steel surface)- essentially hardening the surface of the steel (wear resistance), increasing the corrosion resistance, and to some extent increasing lubricity. In other words the same effect can be reached by different chemical processes. (It is not the black that you see-- that is an additional layer of paint was applied on all Gen1-4 Glocks, until Gen5 when it became a electrolytic applied protective coating).

Calling it by a brand name (tenifer) does not change its effects.

The chemical process itself is a common industrial ( chemical) steel treatment process - done without a brand name attached. This process is NOT "banned because of cyanide".

Contrary to the MYTH : Glock did not stop using Tenifer because of US environmental or EPA concerns. Salt bath nitriding is a common steel treatment and STILL currently done by many companies in the USA -- look it up-- there might be a company in your city doing it.

Tenifer is a European registered brand name - still used by other companies. Melonite is a USA registered name for the same process. That same process can also be generic. Clorox is a brand of bleach, and Morton is a brand of salt -BUT not all bleach is Clorox brand, and not all salt is Morton brand. The chemicals are the same.

You can reach the same terminal endpoint result with various approaches to steel "NITRIDING" (the generic term for what Tenifer does to the steel surface)- essentially hardening the surface of the steel (wear resistance), increasing the corrosion resistance, and to some extent increasing lubricity. In other words the same effect can be reached by different chemical processes. (It is not the black that you see-- that is an additional layer of paint was applied on all Gen1-4 Glocks, until Gen5 when it became a electrolytic applied protective coating).

Calling it by a brand name (tenifer) does not change its effects.

2,234 posts

·

Joined 2014

Lots of us have a general idea but I don't think anyone but Glock could say with certainty. cciman's comments were correct if that was something you were pondering. Although you didn't ask it. Can you elaborate on the need for knowledge?

4,162 posts

·

Joined 2004

You mean sold in the US or made in the US? The Tenifer brand name salt bath nitriding has never been used in the US. I believe Melonite is the US available version of Tenifer.

29,905 posts

·

Joined 2017

Good question. When was the frying pan finish last used? I have a Gen 3 G23 that was a police turn in that came with a post-1994 "Law Enforcement Only" magazine and I have a Gen 3 G20 SF that I bought new in 2012 and both appear to have the xlnt and very durable frying pan finish, and I once stated on this forum that I preferred the Gen 3's because of their frying pan finish and I was told that not all Gen 3's have the frying pan finish. I also assumed that that the finish that replaced the frying pan finish started with the Gen 4's.

I wish Mike M was still on this forum. He knew everything there was to know about Glocks.

I wish Mike M was still on this forum. He knew everything there was to know about Glocks.

419 posts

·

Joined 2022

I’ve personally observed exceptions to this. In 2015 I bought a purple label gen 3 g27 brand new from a LGS, Georgia proofs USA gun with the frying pan finish. The shop did high volume sales so it’s not like it sat in their inventory for 6 or 7 years. I remember when it came in, I spotted it right away and picked it up. At that point, it was years without seeing a new Glock with that finish. Was probably an impulse buy because of the finish, lol. Also in 2015, I picked up a brand new gen 3 g17 from a different LGS that I had been frequenting before it came in. It was a Georgia proof USA gun. Again, I grabbed it right away because it had the frying pan finish that had long been absent in new production guns. I remember it had a four letter prefix serial and I’m pretty sure it was a purple label gun also…not 100% sure though. Anyway, I’m not disagreeing with 2009 being the year of disappearance for the frying pan finish…just wanted to mention a couple exceptions.

17,610 posts

·

Joined 2009

The salt bath nitriding process and its safer alternative

Gas ferritic nitrocarburizing (FNC) is a safer and more economical alternative to salt bath nitriding and FNC. Find out more in this article.

S&W took it a step further by finally deciding to acquire their own equipment to perform nitriding.

[/QUOTE]

Most likely, that is what Glock also did...brought it in house, and/or under their personal control - perhaps with better results. But idiot heads in the Glock universe exploded because "Tenifer" brand was no longer in the marketing.

Misinformed (mis-educated) People still confuse steel treatment with surface finish on a daily basis, thinking that the "Tenifer" was what is resistant to the surface scratches. Tenifer or nitriding is applied on the bare steel before the BLACK top surface paint is applied-- it is the top surface that is scratched.

419 posts

·

Joined 2022

I think there’s some confusion regarding tenifer and the frying pan finish. And somehow an incorrect association has been made between the two. At least from talking to people at my LGS and the range over the years. A lot of people really like that finish and want to know what happened to it. I heard a rumor it was discontinued because it was too slippery for LEO’s who were using them. They gave feedback and Glock moved away from it. Probably an urban myth.

27,374 posts

·

Joined 2008

It may be urban myth that the frying pan finish (FPF) was discontinued because of LEO feedback, IDK. I have a 2006 G26 with the FPF and really, really dislike the finish because it is slippery. Woe to the FPF owner if he/she had to manipulate the slide in the rain/wet and/or is tired.

1,662 posts

·

Joined 2016

What people are referring to as tenifer =/= frying pan finish. FPF was used when Gen 4 was introduced and was used at least into 2013. They then had some guns with the chalky finish for awhile then settled into what's used on new Gen 3's and 4's today.

3,879 posts

·

Joined 2018

Guns made up to 2009 have tenifer under the surface coating. The top coating appears as a frying pan finish. This is possibly the most durable Glock finish. But very slippery if wet or sweaty hands( the slide).The top coat made before this (not sure when it started) was a parkerized? Looking matte finish. Thats extreamly durable too but it does wear the top coat off. Then it looks silver underneath it. In 2009/2010 they made a frying pan finish that did not have tenifer under it. Some refer to these as zebra guns(cause of the barrel).This is still extremely durable but will wear off/rust. The latest gun(s) I personally have that have been dated by Glock were made late in 2014. Ive got a G31.3 10/1/14, and a G21.3SF same date too. They made Austrian and USA guns with this finish. Im pretty sure production of this finish stopped in 2014. But, I could be wrong. Ive got several of these later frying pan finish guns. USA and Austrian guns. Im unaware of when the runs were stopped, and if or when gen 3 or 4 guns were made later. Or even if production stopped on what models with what finish? The best way to find out is to contact Glock and ask for a production date. This finish also has a sheen like a crackle paint used on the bottom metal panels of automobiles in the late 80s, early 90s. Use a magnifying glass if in doubt. Keep in mind that just cause you have a durable finish Glock the barrels can rust or pit .

158 posts

·

Joined 2013

I know they aren’t the same but when people are asking for the tennifer finish they’re wanting the frying pan finish. I bought a Glock 26 in 2013 and it has the FP finish. Carry gun and shows zero holster wear, it is good. I bought a g19 around the same time and it had the chalkier finish.

17,610 posts

·

Joined 2009

Then they are wrong and misinformed -- the cosmetic "finish" is applied on top of the treated or tenifered metal and has nothing to do with the misunderstood "wear resistance" of the gun. You are talking about the texture of the paint being like a frying pan, and it is mythical.What people are referring to as tenifer =/= frying pan finish. FPF was used when Gen 4 was introduced and was used at least into 2013. They then had some guns with the chalky finish for awhile then settled into what's used on new Gen 3's and 4's today.

The Tenifered metal, or Glock treated steel, is under the paint. The holster wear is on the paint, not the nitrided steel.

17,610 posts

·

Joined 2009

There was no special Glock paint that comprised the "frying pan finish"-- and the identification and/or differentiation of the "FPF" by individual users and between discussions, is suspect to complete bias.

17,610 posts

·

Joined 2009

Nitriding of bare steel (even with Tenifer) only penetrates a very thin layer on the surface of the steel. The additional hardness, and corrosion resistance, by nitriding, is only increased on the surface of that piece. It does not make the steel impervious - it can still be cut (slide milled), drilled, scratched, dented, bent, and rust.- but less so than untreated or just painted steel.

tercel89

Discussion starter

5,192 posts

·

Joined 2005

I'm the original poster and I was asking about the last year of use of Tenifer on Glock pistols. I know it is a metal treatment. I dont give a rats a$$ what the "finish" looks like. The reason I like Tenifer is because with my older Glocks that have it , they havent rusted at all even when I wear them in the rain for 12 hour periods of time .

419 posts

·

Joined 2022

One of my LGS has an indoor range and they have a whole catalog of rentals…dozens and dozens…and multiples of the same model. When these guns fulfill their rental lifespan, they’re sold as former range guns. I believe they’re marked with an orange tag before they hit the showroom floor. These guns are subjected to thousands of rounds of mileage with little to no cleaning/maintenance. Due to the extreme amount of filth, these guns are very generously discounted. Anyway, years ago they had a gen 3 g24c with the fpf finish that I decided to pick up. Upon disassembling of the slide, it was so bad I decided to use a toothbrush style copper bristle brush to clean it. The most stubborn part was the carbon caked ported area of the slide and barrel. I went crazy with the brush and removed everything. After rinsing with solvent and wiping down everything, the gun looked brand new without a single scratch or blemish. I realize copper bristles are softer than the slide and barrel, but still…that FPF finish is tough and durable, as long as you can live with the slipperiness. I know guys that will buy any used Glock in 9mm with that finish, for a fair price.

17,610 posts

·

Joined 2009

Tenifer is not magical, nor special. For wearing in the rain or other non-salt water applications, you are not going to have a problem, whether it was Tenifer, or other nitride process.

833 posts

·

Joined 2021

I've gotten rust on nearly every non-stainless gun I own, and even one stainless S&W that just loves to rust! I have yet to find any rust on any of my Glocks nor on my NP3 plated 1911's. I do love the NP3 plating although I cannot bare the thought of shooting them dry as recommended by Robar. Too bad they no longer do the NP3 plating as I have a couple of guns I'd like to have done. Oh well, waited too long!

Cheers

crkckr

Cheers

crkckr

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 22M

- members

- 203K

- Since

- 1999

A forum community dedicated to Glock firearm owners and enthusiasts. Come join the discussion about optics, gunsmithing, styles, reviews, troubleshooting, accessories, classifieds, and more!

Explore Our Forums