Probably the most common mold is the TC style bullet in 175 or 180 grain. That said the question you have to answer is how much volume do you anticapate?

The reason I ask is there are 1, 2, 3, 4 and 6 cavity molds.

Aluminum molds are lighter in weight so you don't get as fatigued over longer periods of casting, they cool off quicker . Draw back is they can be damaged more easily.

Brass molds work well too but at increased weight. Draw back is they can be damaged more easily.

Steel molds are heavier, retain heat and are rugged.

If you're looking for a cheaper mold to get you started I would suggest the LEE 6 cavity mold. The 6 cavitys from LEE are better over all and it will produce some nice bullets fast.

http://www.midwayusa.com/Product/56...-cavity-bullet-mold-401-175-tc-40-s-and-w-401-diameter-175-grain-truncated-cone

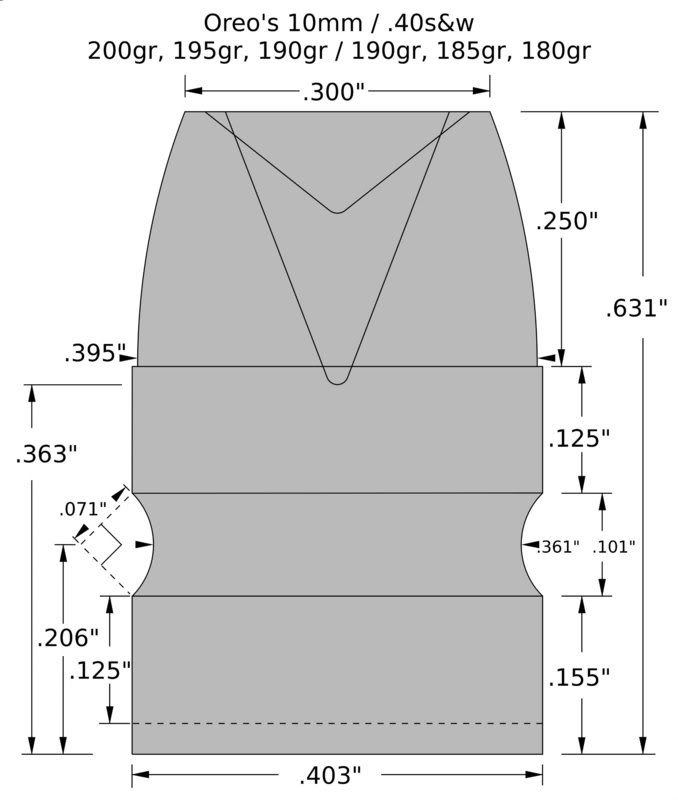

However there are many different types and bullet shapes to consider, even molds that have change able pins for different nose shapes, these are usually a hollow point or if a flat pin is used the flat nose.

The mountain Mold Co. can make you a custom mold to order.

http://mountainmolds.com/

Lyman used to produce and sell a single cavity 156gr Devastator Hollow Point mold for 10mm/40 cal, but they are now obsolete despite them still selling them in 357/9mm, 44 and 45cal. I have all of these and they are time consuming as you are working with the hollow pointer pin and single cavity mold.

I use the Lyman 4 cavity 175gr TCBB (turncated cone belvel base), RCBS 2 cavity 175 gr TC SWC, and 200gr TC SWC. The SWC (semi wad cutter) cut clean holes in paper targets which is better for scoring, if that is important to you.

Good luck wit your decision!